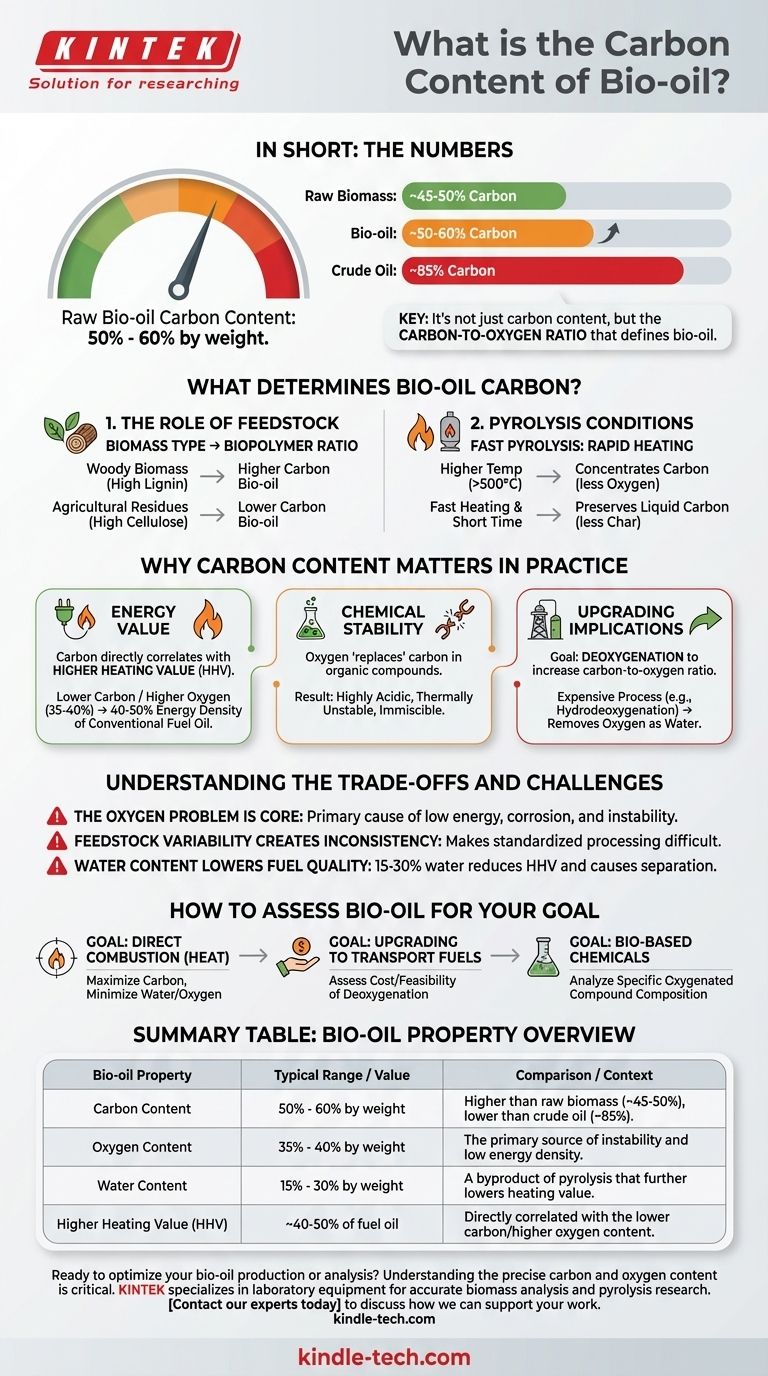

En bref, la teneur en carbone du bio-huile brut varie généralement de 50 % à 60 % en poids. Cette valeur est très variable et représente une augmentation significative de la densité de carbone par rapport à la biomasse d'origine (environ 45-50 %), mais elle reste substantiellement inférieure à celle du pétrole brut conventionnel (environ 85 %).

La caractéristique distinctive du bio-huile n'est pas seulement sa teneur en carbone, mais sa relation avec une très forte teneur en oxygène. Comprendre ce rapport carbone-oxygène est la clé pour évaluer son potentiel et ses défis en tant que carburant renouvelable ou matière première chimique.

Qu'est-ce qui détermine la teneur en carbone du bio-huile ?

Le pourcentage final de carbone dans le bio-huile n'est pas un nombre fixe. Il est le résultat d'une interaction complexe entre la matière première de départ et la méthode précise utilisée pour la convertir.

Le rôle de la matière première

La composition chimique de la biomasse de départ établit la ligne de base initiale. Différents matériaux végétaux ont des rapports différents de biopolymères clés.

Par exemple, la biomasse ligneuse est riche en lignine, un polymère complexe avec un rapport carbone-oxygène plus élevé. Le bio-huile produit à partir de matières premières riches en lignine, comme les bois durs ou les résidus forestiers, aura généralement une teneur en carbone plus élevée.

Inversement, les résidus agricoles comme les graminées ou les pailles sont plus riches en cellulose et hémicellulose. Ceux-ci ont plus d'oxygène dans leur structure chimique, ce qui donne un bio-huile avec une teneur en carbone relative plus faible.

L'impact des conditions de pyrolyse

La pyrolyse rapide est le processus thermochimique utilisé pour créer du bio-huile. Elle implique un chauffage rapide de la biomasse en l'absence d'oxygène. Les conditions spécifiques de ce processus influencent de manière critique le produit final.

- Température : Des températures de pyrolyse plus élevées (par exemple, >500°C) peuvent favoriser les réactions de craquage secondaire. Cela peut décomposer des molécules plus grandes, potentiellement en expulsant plus d'oxygène sous forme d'eau (H₂O) et d'oxydes de carbone (CO, CO₂), concentrant ainsi le carbone dans le bio-huile liquide restant.

- Taux de chauffage et temps de résidence : Des taux de chauffage rapides et des temps de résidence des vapeurs courts sont les caractéristiques de la pyrolyse rapide. Ceci est crucial pour maximiser le rendement liquide et empêcher les vapeurs de bio-huile de se dégrader en gaz non condensables et en excès de charbon, ce qui préserve le carbone dans le produit liquide souhaité.

Pourquoi la teneur en carbone est-elle importante en pratique ?

Le pourcentage de carbone est un indicateur de plusieurs des propriétés les plus importantes du bio-huile, dictant comment il peut être utilisé et les défis à surmonter.

Impact sur la valeur énergétique

Le rôle le plus critique du carbone est sa corrélation directe avec le Pouvoir Calorifique Supérieur (PCS) du carburant. Le carbone et l'hydrogène sont les principaux éléments qui libèrent de l'énergie pendant la combustion.

Parce que le bio-huile a une teneur en carbone plus faible et une teneur en oxygène beaucoup plus élevée (35-40 %) que les combustibles fossiles, sa densité énergétique est significativement plus faible – environ 40-50 % de celle du fioul conventionnel.

Influence sur la stabilité chimique

L'élément qui "remplace" le carbone dans la composition du bio-huile est l'oxygène. Cette teneur élevée en oxygène est répartie sur des centaines de composés organiques différents, y compris des acides, des aldéhydes et des cétones.

Cela rend le bio-huile brut très acide (corrosif), thermiquement instable (il peut polymériser et s'épaissir avec le temps) et immiscible avec les carburants hydrocarbonés.

Implications pour l'amélioration

Pour être utilisé comme carburant "drop-in" pour les moteurs ou les raffineries existants, le bio-huile doit être amélioré. L'objectif principal de l'amélioration est la désoxygénation – l'élimination des atomes d'oxygène pour augmenter le pourcentage relatif de carbone et d'hydrogène.

Des processus comme l'hydrodésoxygénation ajoutent de l'hydrogène sous pression pour réagir avec l'oxygène, l'éliminant sous forme d'eau. Il s'agit d'un processus coûteux et énergivore, mais il est essentiel pour produire un carburant hydrocarboné stable et à haute densité énergétique à partir du bio-huile initial.

Comprendre les compromis et les défis

Bien que la conversion de la biomasse en un liquide dense en carbone soit une étape majeure, le bio-huile résultant s'accompagne de complications inhérentes qui doivent être abordées pour une application pratique.

Le problème de l'oxygène est le problème central

La teneur élevée en oxygène est le plus grand obstacle technique à l'utilisation généralisée du bio-huile. Elle est directement responsable de la faible valeur énergétique, de la corrosivité et de l'instabilité du carburant. Chaque défi en aval est, d'une certaine manière, lié à la présence de trop d'oxygène.

La variabilité de la matière première crée une incohérence

La dépendance au type de matière première et aux conditions de processus signifie que le bio-huile n'est pas une marchandise standardisée comme le pétrole brut. Cette incohérence rend difficile la conception et l'exploitation d'installations de conversion et d'amélioration capables de gérer une entrée variable tout en produisant une sortie cohérente.

La teneur en eau abaisse la qualité du carburant

Au-delà de la composition élémentaire, le bio-huile contient également une quantité significative d'eau (15-30 %), qui est un sous-produit des réactions de pyrolyse. Cette eau réduit davantage le pouvoir calorifique par unité de masse et peut causer des problèmes de séparation de phase pendant le stockage.

Comment évaluer le bio-huile pour votre objectif

Votre évaluation de la teneur en carbone du bio-huile dépend entièrement de votre application prévue.

- Si votre objectif principal est la combustion directe pour la chaleur : Recherchez un bio-huile avec la teneur en carbone la plus élevée possible et la teneur en eau et en oxygène la plus faible pour maximiser son pouvoir calorifique (PCS).

- Si votre objectif principal est l'amélioration pour les carburants de transport : La teneur en carbone initiale est moins importante que la faisabilité et le coût de la désoxygénation pour augmenter considérablement le rapport carbone-oxygène.

- Si votre objectif principal est la production de produits chimiques biosourcés : La teneur en carbone globale n'est qu'un point de départ ; vous devez analyser les composés chimiques oxygénés spécifiques qui peuvent être extraits en tant que produits chimiques de plateforme précieux.

En fin de compte, comprendre les facteurs qui contrôlent la teneur en carbone du bio-huile est la première étape vers l'ingénierie de solutions qui libèrent son potentiel en tant que ressource durable.

Tableau récapitulatif :

| Propriété du bio-huile | Plage / Valeur typique | Comparaison / Contexte |

|---|---|---|

| Teneur en carbone | 50 % - 60 % en poids | Plus élevée que la biomasse brute (~45-50 %), mais plus faible que le pétrole brut (~85 %) |

| Teneur en oxygène | 35 % - 40 % en poids | La principale source d'instabilité et de faible densité énergétique du bio-huile |

| Teneur en eau | 15 % - 30 % en poids | Un sous-produit de la pyrolyse qui abaisse davantage le pouvoir calorifique |

| Pouvoir Calorifique Supérieur (PCS) | ~40-50 % du fioul | Directement corrélé à la teneur en carbone plus faible/en oxygène plus élevée |

Prêt à optimiser votre production ou analyse de bio-huile ?

Comprendre la teneur précise en carbone et en oxygène de votre bio-huile est essentiel pour évaluer sa qualité et ses applications potentielles. Chez KINTEK, nous sommes spécialisés dans les équipements de laboratoire et les consommables nécessaires à l'analyse précise de la biomasse et à la recherche sur la pyrolyse.

Que vous développiez de nouvelles matières premières, optimisiez les conditions de pyrolyse ou analysiez la composition chimique de votre bio-huile, nos outils fiables peuvent vous aider à obtenir des résultats cohérents et de haute qualité.

Contactez nos experts dès aujourd'hui pour discuter de la façon dont KINTEK peut soutenir le travail de votre laboratoire dans les énergies renouvelables et les matériaux durables.

Guide Visuel

Produits associés

- Stérilisateur de laboratoire Autoclave de laboratoire Stérilisateur à vapeur sous pression vertical pour écran à cristaux liquides de type automatique

- Petite usine de pyrolyse continue à four rotatif électrique pour le chauffage

- Presse Thermique Automatique de Laboratoire

- Instrument de tamisage électromagnétique tridimensionnel

- Électrode à disque rotatif (disque-anneau) RRDE / Compatible avec PINE, ALS japonais, Metrohm suisse carbone vitreux platine

Les gens demandent aussi

- Quel rôle joue un autoclave dans le traitement acide pour la rupture des microalgues ? Optimisez le prétraitement des cellules à haut rendement

- Quelles conditions expérimentales les autoclaves en acier inoxydable fournissent-elles pour la lixiviation PCT-A ? Optimiser les tests de verre phosphaté

- Quelle est la nécessité d'utiliser un autoclave pour le prétraitement des milieux de culture ? Assurer des tests précis sur Ag2O/TiO2

- Quelle est la fonction principale et le principe de l'autoclavage ? Maîtriser la stérilisation en laboratoire avec de la vapeur à haute pression

- Quel rôle jouent les autoclaves de laboratoire dans l'extraction de la pectine ? Optimiser le rendement prébiotique de la biomasse d'agrumes et de pommes